ESG Topics A-Z

Packaging

To PepsiCo:

PepsiCo relies on diverse packaging solutions to deliver products to our customers and consumers without compromising food safety or quality. When designed sustainably, packaging solutions can contribute to the creation of a circular value chain and potentially help reduce our GHG footprint. PepsiCo's sustainable packaging vision is to build a world where packaging never becomes waste.

To the World:

When packaging is disposed of improperly, it may end up as waste in the marine environment or on land, impacting both human health and the health of the environment. This urgent global issue requires a systemic shift to more sustainable solutions for delivering products to our consumers through multi-stakeholder collaboration and active partnerships within the value chain.

Approach

Packaging plays an essential role in safely delivering our products to customers and consumers. We design our packaging to balance several critical criteria, including compliance with food safety regulations, maintaining quality of the product, environmental sustainability, affordability and consumer preferences, including convenience. Through our pep+ (PepsiCo Positive) agenda, we are working to make every stage of our value chain more circular and to tackle significant global packaging challenges through innovation, re-design, policy advocacy and infrastructure investment. Our sustainable packaging efforts support our pep+ ambition to create a Positive Value Chain by contributing to more circular and sustainable systems and providing our consumers with innovative solutions and business models.

Our sustainable packaging vision

PepsiCo’s sustainable packaging vision is to build a world where packaging never becomes waste. We take a three-pronged approach to realizing our vision:

- Reducing the amount of packaging we use;

- Driving recycling and a circular economy for recycled materials; and

- Reinventing how we deliver products through new business models with low or no packaging options, including reuse models and new materials.

Making progress across these pillars aims to help us develop appropriate end-of-life solutions and improve the carbon footprint of our packaging, as well as other environmental impacts. As we tackle our packaging ambitions, we will continue to strive for protection of human rights, especially for workers in the informal recycling sector. Through each of these three pillars, PepsiCo aims to lead change through active partnerships and stakeholder engagement.

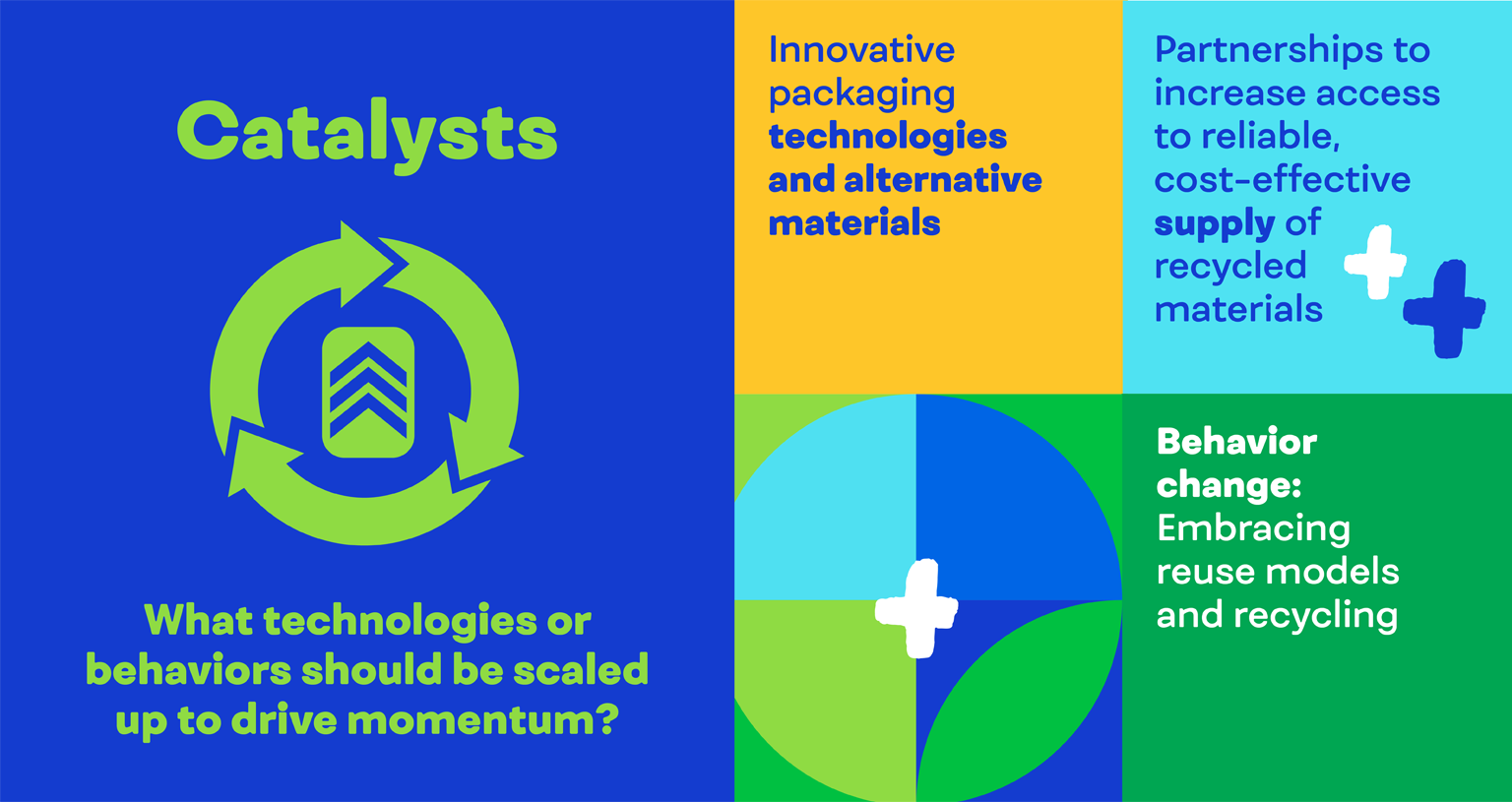

The challenges in this journey are significant and complex, and we are facing global and systemic obstacles along the way. We know that no one company or industry can create a circular economy on its own. Sustainably managing our packaging requires comprehensive solutions, many of which are complex and hinge on significant systemic transformations such as infrastructure, policy or consumer engagement. We are working together with our stakeholders, including governments, NGOs, suppliers, customers, peer companies, consumers and more, to find scalable solutions. To achieve these transformations, multi-stakeholder collaboration and action-oriented partnerships within the packaging value chain are needed. This will not only help us, but also further help build a circular economy for packaging that benefits us all.

The following goals make up our pep+ packaging agenda:

By 2025:- Design 100% of packaging to be recyclable, compostable, biodegradable or reusable.1

- Invest to increase recycling rates in key markets.

- Cut virgin plastic from non-renewable sources per serving across our global beverages and convenient foods portfolio by 50% through:2

- Scaling new business models that avoid or minimize single-use

packaging materials (e.g., models that reuse, refill, prepare at

home, utilize concentrates like powders, drops, etc.), with the aim of delivering 20% of all

beverage servings we sell through reusable models.3

- Reducing our absolute tonnage of virgin plastic from non-renewable sources by 20%, including by seeking to:2

- Use market-leading bio-based and renewable materials.

- Achieve our goal of using 50% recycled content in our plastic packaging.

- Scaling new business models that avoid or minimize single-use

packaging materials (e.g., models that reuse, refill, prepare at

home, utilize concentrates like powders, drops, etc.), with the aim of delivering 20% of all

beverage servings we sell through reusable models.3

pep+ in context: Packaging

Reduce the plastic that we use

Reducing plastic packaging supports our climate ambition by decreasing the amount of virgin, fossil-fuel based plastic we put on the market. We estimate that our efforts to reduce packaging could eliminate 400,000 metric tons of virgin plastic material by 2030. To reduce plastics across primary, secondary and tertiary packaging, we have made progress in light-weighting our bottles, reducing thickness of our films and reducing shipping and other packaging materials. Our R&D teams are developing new technology to pre-settle our snacks products in order to use a smaller bag for the same amount of product, further reducing our use of plastic.

Recycle: support a circular economy for plastic

Designing for circularity

We currently project that, by 2025, we will have designed 98% of our packaging to be recyclable, compostable, biodegradable or reusable (RCBR) and that 92% of our packaging will be overall RCBR — that is, both designed to be RCBR and RCBR based on availability of end-of-life solutions. This current projection has us short of our 100% goal, but we continue with our ambition to innovate, invest and partner to progress further. We will continue to engage externally and across industries to collaborate on the essential shifts needed to support this transformation.

Incorporating recycled materials

Achieving circularity for PET and other plastics is contingent on both demand and supply. Robust demand increases material value and creates market pull, which helps unlock new supply. We have set our recycled material incorporation ambition to send such a demand signal and help drive towards circularity.

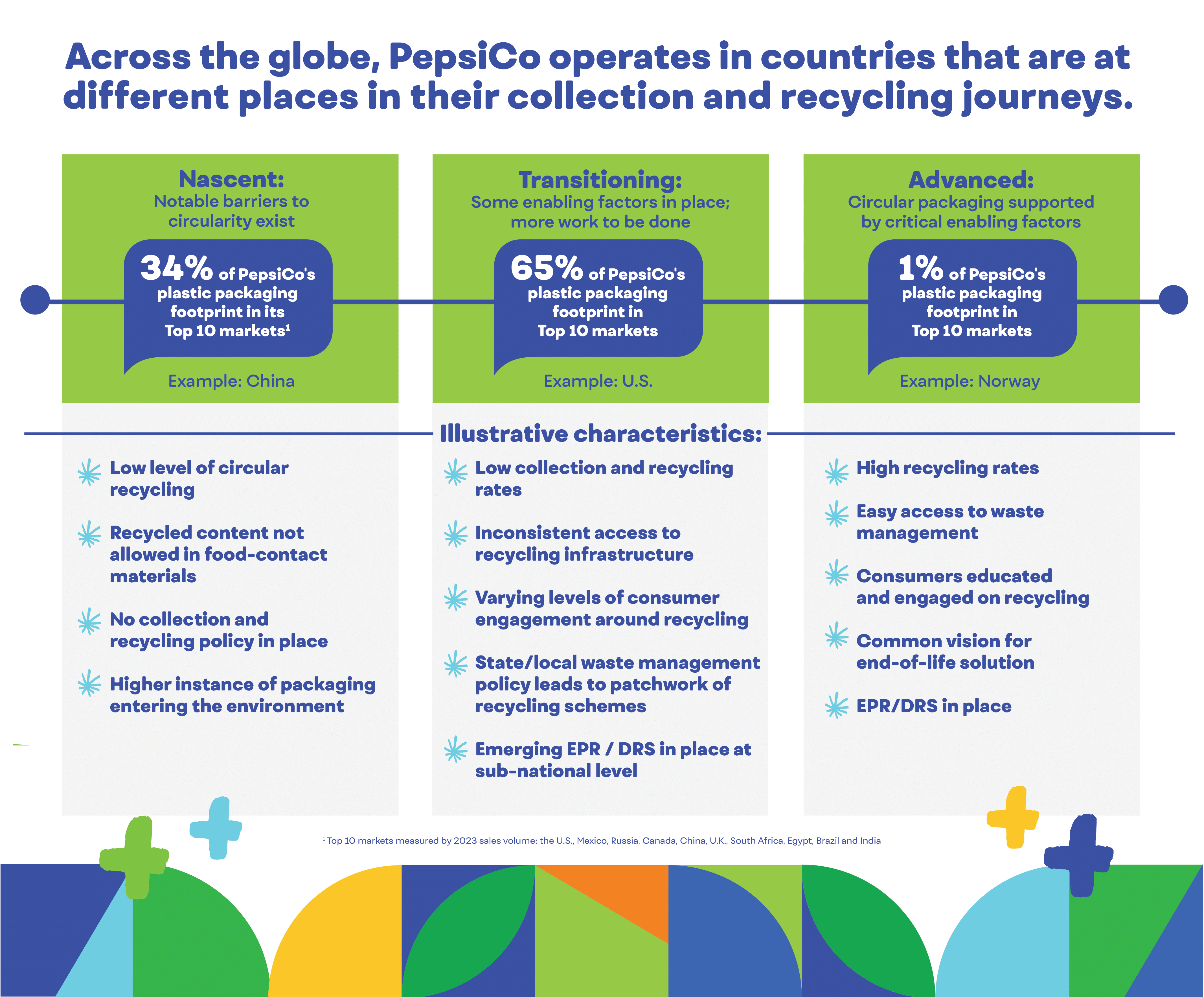

Supporting recycling systems

Once enjoyed, the packaging from our products should be collected and recycled where possible for another use to create a more circular economy. We recognize that, while we cannot change recycling and recovery rates around the world on our own, we have a role to play in supporting recycling systems through investments and partnerships. Increasing collection and recycling rates supports a circular economy by promoting the recovery of the materials we put into the market, preserving their value and aiming to prevent the materials from ending up as litter or in landfills. We seek to improve collection through policy and voluntary programs supporting both infrastructure and consumer education and engagement to increase recycling rates.

Throughout all of these efforts, we are striving to promote a safe and inclusive waste management system for those working informally in the sector. The informal waste sector exists across the globe, filling the gap where formal collection and recycling systems are lacking. Informal sector workers, including waste pickers, often operate in unsafe conditions, without employment benefits accorded to those in formal employment, and experience income disparity. That is why PepsiCo has signed onto the Fair Circularity Initiative to create a just transition to a circular economy.

Reinvent: improve the packaging and plastic that we use

PepsiCo’s reinvention efforts focus on improving the environmental impact of our packaging by developing plastics from non-food, plant-based sources and exploring biodegradable or compostable options, as well as reuse models.

Using alternative materials

PepsiCo is a member of several consortia and partnerships to develop innovative packaging solutions. These include co-founding the Composting Consortium. The group is managed by the investment firm Closed Loop Partners (CLP) and aims to define best practices within the compostable packaging value chain, test various composting technologies, identify enabling environment factors that support the industry’s development and outline the business case for greater investment in this emerging space.

Scaling reuse models

We’re also reinventing our offerings to deliver high-quality convenient foods and drinks through reusable packaging and innovative reuse models that eliminate the need for single-use plastic. These models can help us reduce our use of virgin plastic per serving, decouple business growth from virgin plastic use and, over time, decrease GHG emissions. Informed by the Ellen MacArthur Foundation’s reuse framework, we are pursuing four approaches to scale reuse:

- Expanding SodaStream;

- Building out our returnable plastic and glass bottle offerings in partnership with PepsiCo bottlers;

- Driving adoption of reusable cups for our fountain drinks; and

- Accelerating growth in refill at home models, including powders and concentrates.

Our early forays into reusable packaging have shown us that we need different solutions for different markets and consumption occasions, and that consumer convenience is critical to success. With this in mind, we are working to develop localized playbooks for different reuse models to help our markets deploy refillable packaging in ways that will be most appropriate to their local environment. In the future, partnerships for sharing logistics and cleaning facilities could improve the scale and uptake of these types of reuse systems.

Governance

A dedicated team led by our Vice President of Packaging manages PepsiCo’s sustainable packaging programs. The team reports to the PepsiCo Executive Committee through our Chief Sustainability Officer but partners closely with many internal functions, including Global Procurement, Corporate Affairs, Research and Development, Marketing and our Human Rights Operating Council. Together, the cross-functional team monitors and evaluates packaging challenges on an ongoing basis, including progress against our goals, and shares information for review by our PepsiCo Executive Committee as well as the Sustainability, Diversity and Public Policy Committee of our Board of Directors on at least an annual basis.

PepsiCo publicly discloses key packaging metrics and progress towards our goals. In addition to the information about our packaging strategy and progress covered here, on our ESG Summary and in our annual report, we report annually through the Ellen MacArthur Foundation’s New Plastics Economy Global Commitment Progress Reports.

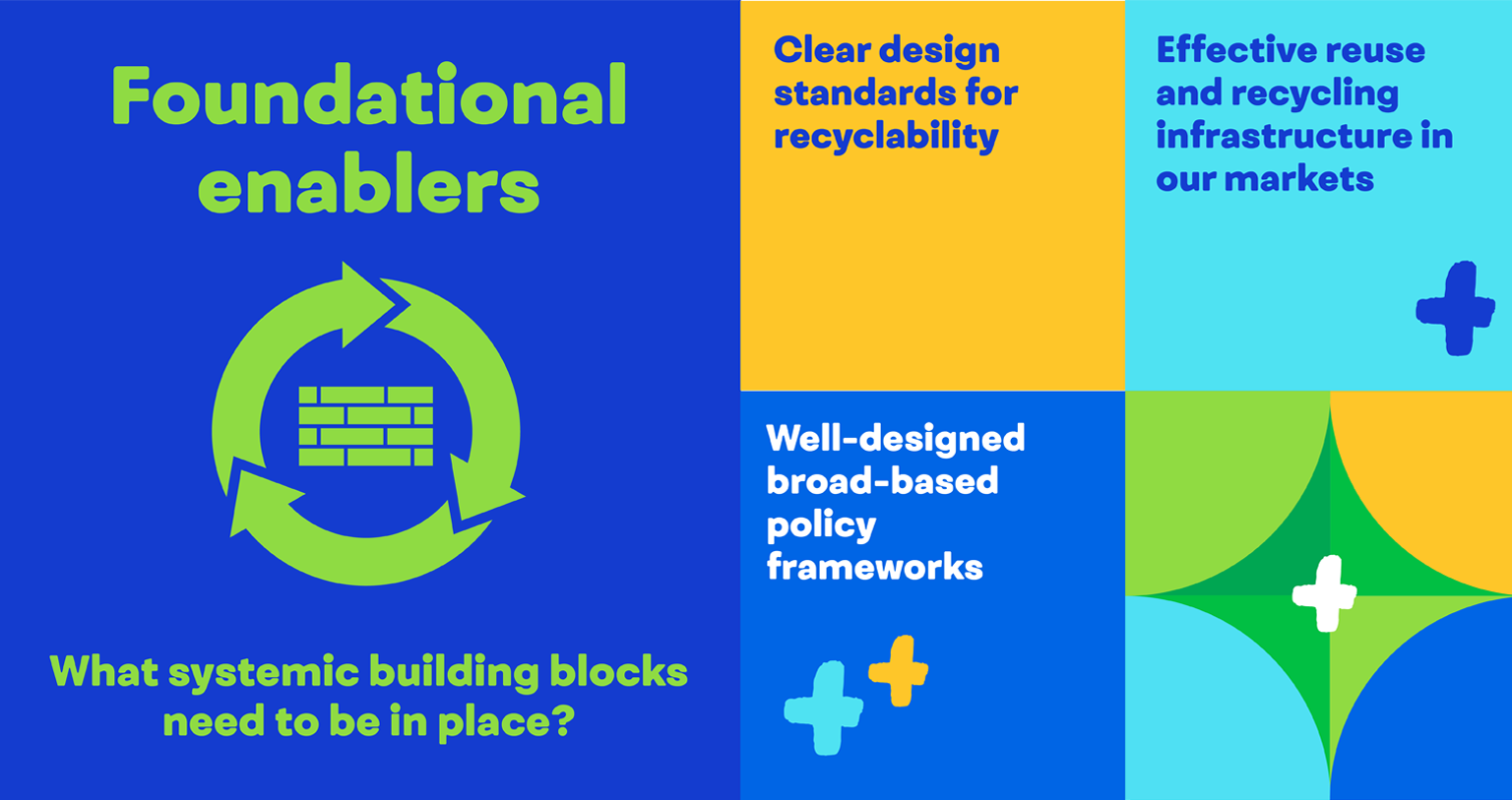

Constructive policy engagement and advocacy

PepsiCo recognizes the valuable role public-private partnerships can play in improving waste management and promoting the efficient use of valuable resources. We believe it is important for PepsiCo and other industry members to engage proactively and constructively in policy discussions. We actively support policy proposals that are broad based, deliver positive environmental outcomes, provide incentives for sustainability and allow us to contribute to the design and implementation of the programs. Our vision demands action and investment from all stakeholders — consumers, participants within the packaging value chain and local, state and national governments.

We participate in public policy dialogues to share our expertise on key issues that support our business strategy and, where we can, contribute ideas that help our business, our consumers and society thrive in a sustainable fashion and work towards building a circular economy. Packaging policy was among our key policy issues in 2023. In particular, we engaged on:

Extended Producer Responsibility

We actively advocate for policies, at global, national and local levels, that promote a circular economy for packaging, including well-designed Extended Producer Responsibility (EPR) programs managed by the industry with government oversight. EPR programs extend producers’ responsibility for end-of-life management of products and, if properly designed and funded, can provide meaningful support for collection and recycling, as well as upstream measures such as design. PepsiCo has extensive experience participating in EPR programs in different parts of the world, and we use our experience and insights to deliver constructive recommendations when such programs are being pursued or developed.

Our view is that EPR programs function best when input, cooperation and funding come from key stakeholders. We actively engage with the industry to develop useful guidance on best-in-class EPR program design, such as the guidance put forward by the Consumer Goods Forum Coalition of Action on Plastic Waste. We also collaborate with a broad range of key stakeholders around the world, including NGOs and other industry actors, to promote a better understanding of where and how EPR programs may work best. Additionally, we are now hands-on engaged in standing up EPR programs, including through our partnership with Circular Action Alliance in the U.S.

Global Plastics Treaty

PepsiCo is a member of the Business Coalition for a Global Plastics Treaty, advocating for an ambitious United Nations (UN) global agreement to end plastic pollution. We believe a global treaty setting a common global framework and legally binding rules for national action has potential to spur rapid progress towards a circular economy for packaging. PepsiCo supports action within the value chain in the areas of reduction, circulation and waste prevention. The treaty could benefit those working towards a circular economy by:

- Aligning definitions and metrics across regions (like the definition of “recyclable”);

- Harmonizing measures to improve packaging design; and

- Improving waste management systems including smart EPR based on industry aligned principles.

We know working towards more sustainable packaging solutions is a complex endeavor — one that will require collaboration from national, state and local governments, the private sector and NGOs. This, coupled with effective and well-designed policy, will support a shift towards a circular economy. PepsiCo is supportive of global action and is dedicated to being part of the solution.

Progress

In 2023, we used approximately 2.6 million metric tons of plastic to package products throughout our convenient foods and drinks portfolio, including primary, secondary and tertiary packaging.

Progress

- We announced a North American rollout of paper solutions to replace plastic rings on beverage multipacks, becoming the first beverage company to do so.

- As of the end of 2023, we sold products in returnable bottles in more than 75 international markets.

- We opened the doors to the Greenhouse Learning Center in Plano, Texas, a first-of-its-kind facility dedicated to advancing progress on compostable packaging.

- We helped set up a voluntary EPR program for the collection and reuse of flexible packaging in Thailand. The program Journey to Zero Waste collected 1,000 metric tons of flexible films in 2023.

Challenges

- Business growth in certain markets, particularly in markets that do not allow, or have only recently allowed, rPET in food grade packaging, has presented challenges to virgin plastic reduction.

- Inadequate infrastructure and low recycling rates make collection and recycling of packaging difficult and increase the likelihood of packaging leaking into the environment.

- Limited supply of high-quality recycled materials makes it difficult to meet our demand for recycled content in our plastic packaging.

- Consumer comfort with single-use and ready-to-drink models creates challenges for transitions to reuse/refill solutions.

Reduce the plastic that we use

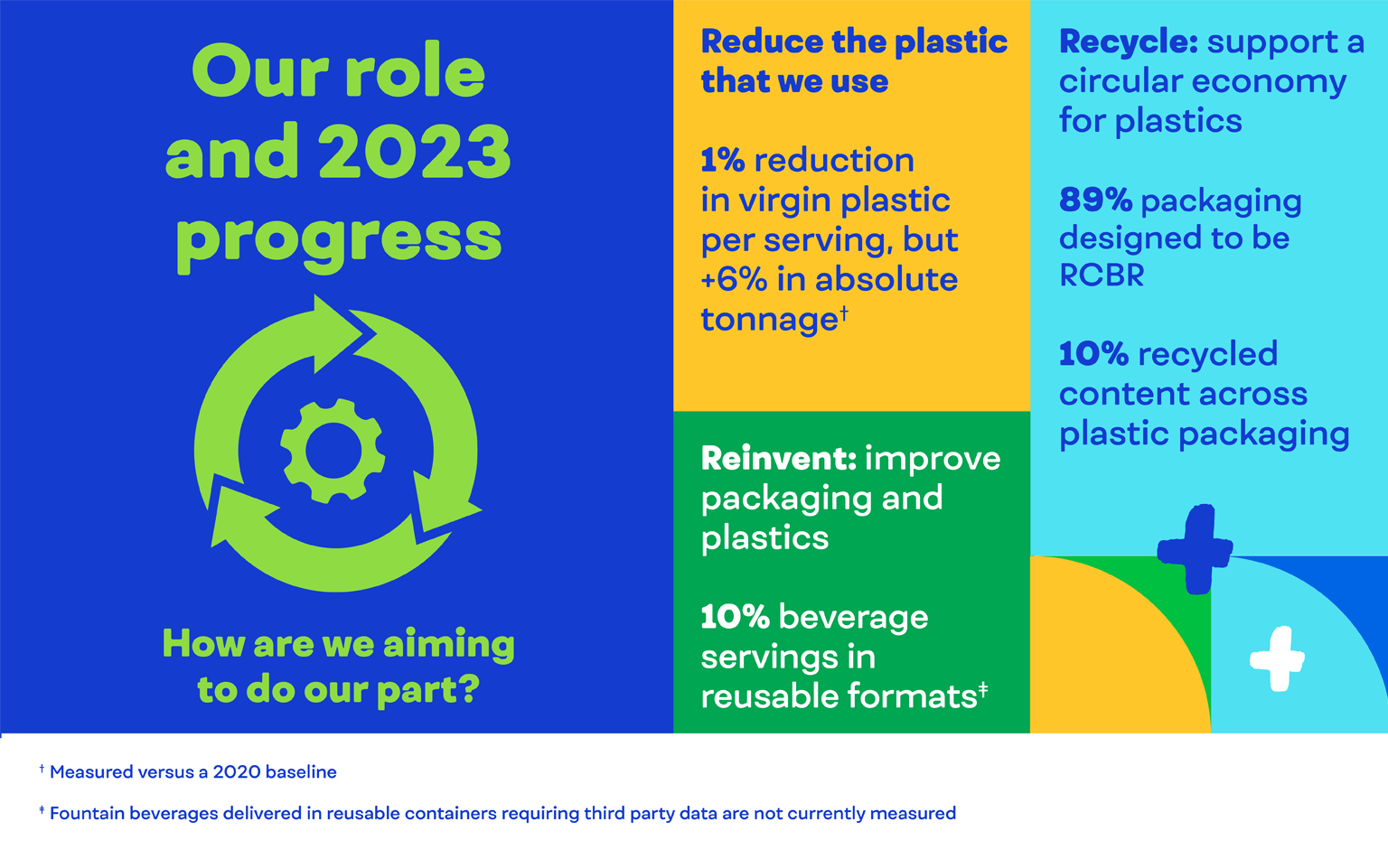

While achieving our packaging goals comes with a unique set of challenges to overcome, we continued to work toward our ambitions in 2023. Overall, the virgin plastic footprint of our convenient foods and drinks portfolio has decreased by 1% per serving against a 2020 baseline — but has increased 6% in absolute terms.

Within our convenient foods business, we are implementing new technology to change the way we package our snacks.

Recycle: support a circular economy for plastic

Designing for circularity

In 2023, 89% of our packaging worldwide was RCBR. While we phase out materials that are challenging in the recycling process, such as non-recyclable labels, we continue searching for solutions to improve the recyclability of flexible snacks packaging and to increase consumer access to recycling for materials like shrink wrap, which present a challenge to PepsiCo and the industry overall.

Incorporating recycled materials

Across our global company-owned and franchise beverage operations, in 2023, we used 10% recycled plastic in plastic packaging globally. More than 30 markets offered products packaged in 100% rPET (excluding caps and labels). In all, more than 60 markets had at least one PepsiCo product with rPET in its packaging in 2023. Efforts contributing to this progress include:

- Introducing the first 100% rPET carbonated beverage bottle in India with Pepsi Black (also known as Pepsi Max or Pepsi Zero Sugar in other markets).

- Introducing 100% rPET bottles for several products in the UAE, including Pepsi and Diet Pepsi.

- Building on prior rPET expansion efforts in our APAC operations, we launched 100% rPET bottles in Thailand.

- Now making Pepsi bottles in Uzbekistan with 20% rPET — making PepsiCo the first beverage company to use rPET in the country.

- Nearly doubling the percentage of rPET in our North America beverages packaging in 2023. Additionally, several brands including Pepsi, Pepsi Zero, Mountain Dew, Starry and Aquafina are offering products in bottles made from 100% recycled PET. We plan to convert all Pepsi-branded products in the U.S. to 100% rPET bottles by 2030.

Following years of advocacy to allow for the use of recycled content in food packaging, the launch of rPET bottles in India became possible after the Food Safety Standards Authority of India approved its use, following a thorough review of the material regarding food safety and compliance with its guidelines.

In 2023, we launched a partnership with GreenDot to invest in technology and solutions that enable integration of 50% recycled content4 into our Sunbites chips packaging in the U.K. This partnership is turning what was once plastic waste into food-grade packaging material, with the potential to eliminate 200 metric tons of fossil-based plastic across Sunbites packaging by the end of 2025.

Improving recycling systems

As we work to contribute to a circular economy, we supported collection, recycling and composting systems. We worked with a variety of partners to drive improvements in both the formal and informal recycling economies.

In 2023, we participated in Closed Loop Partner’s Composting Consortium’s Compostable Packaging Disintegration Pilot, a comprehensive and collaborative study to improve available data on how certified, food-contact compostable food ware and packaging are currently breaking down at different composting facilities.

Alongside industry peers, in 2023, we invested in Circular Services, a developer launched by CLP and Brookfield Renewable, whose goal is to build recycling facilities that will enable U.S. cities to abandon the costly practice of dumping waste in landfills by ensuring that valuable commodities are recycled and reused in domestic supply chains. Additionally, in 2023, the PepsiCo Foundation invested $2 million in global recycling partnership initiatives to help elevate recycling rates and waste collection.

In November 2022, PepsiCo joined partners Tearfund, The Coca-Cola Company, Nestle and Unilever to launch the Fair Circularity Initiative and support a set of principles to guide corporate engagement with the informal waste sector and work towards a fairer circular economy. Internally, a cross functional group is working to develop a holistic strategy to implement these principles and further the projects we’ve already engaged in across our markets.

One such example is the Purna Project in India. Through this project, funded by PepsiCo India, the team has focused on efforts to improve ownership of waste, recognition and dignity as well as health and hygiene of the waste pickers, professional benefits and growth and entrepreneurship opportunities. We will use learnings from this and other similar projects to inform our approach.

Reinvent: improve the packaging and plastic that we use

We are continuing to grow our portfolio of alternative materials and “beyond the bottle” models for our beverages.

Alternative materials

We announced in 2023 that we will transition to paperboard packaging to replace plastic rings in North America. In addition to meeting our RCBR standards, the new packaging is easy to implement on shelf for customers, has consumer-friendly branded-design and is made from recyclable materials.

Additionally, in our convenient foods business, we are striving to reinvent our snacks packaging to go beyond film. In 2023, we developed paper-based packaging for our Instant Quaker Oats products in the U.K. Additionally, we trialed paper for secondary packaging of multi-serve packaging of Walker’s chips in the U.K.

Reuse: scale reuse models

In 2023, 10% of our servings were delivered in reusable packaging.5 We currently offer reuse models in more than 80 markets. These models may include, but are not limited to, SodaStream, fountain beverages delivered in reusable containers, returnable glass and plastic bottles, and concentrates and powders sold to customers.

In 2023, we continued to invest in returnable bottles, including by expanding our existing program in Mexico. Additionally, we began implementation of a universal refillable bottle across our brands in Spain. Interchangeable bottles between multiple products make reuse models more efficient by reducing sortation needs and optimizing the bottling process. As of the end of 2023, we have returnable bottle programs in more than 75 global markets.

PepsiCo worked with UEFA (Union of European Football Association) to implement circular economy practices for Pepsi, Lay’s, Doritos and Gatorade packaging at the UEFA Champions League (UCL) Final soccer games. At the Women’s UCL Final at PSV Stadium, PepsiCo deployed reusable packaging and collection systems for its food and beverage products. We also eliminated more than 15,000 disposable cups at the UEFA Champions Festival in Istanbul through a reusable cup initiative in partnership with TURN.

In North America, we piloted a reusable cup solution in Baltimore, Maryland in partnership with TURN, featuring gamification to incentivize consumers to return their cups after use. Through this pilot, all cups at the CGF Arena in Baltimore were transitioned from disposable to reusable.

PepsiCo is leveraging partnerships to identify reuse solutions within the value chain and advocate for smart policies. For example, in 2023, we continued engagement with the Closed Loop Partners NextGen Cup Consortium, a multi-year industry-led group working to accelerate learnings and action on reusable cups in food service. We also joined the Consumer Goods Forum Reuse/Refill workstream, partnering with peer companies and retailers to move beyond pilots towards scaled reuse solutions. We continued our engagement in the World Economic Forum’s Consumers Beyond Waste through which we’ve been working with peer companies and NGOs to align on definitions and measurement methodology for reuse. Together, we are striving to develop return and refill models that will inspire consumers and drive reuse growth.

We also continued to expand our SodaStream portfolio through the launch of two new models (E-Terra and E-Duo) and an automated refill program for CO2 canisters to further improve consumer convenience and customization.

Strategic partnerships

To build a circular economy for packaging, it is important that all actors in the packaging value chain, including packaging producers, retail and sales outlets, waste management and recycling industries, governments and consumers work together to collectively achieve this transition. To this end, PepsiCo engages in a variety of programs and initiatives that aim to bring stakeholders together in an effort to create broad solutions in order to shift the system in a more sustainable direction. Due to the breadth of our global, regional and local partnerships, we cannot list every initiative in all markets and focus here on a representative sample of our work and commitment to collaboration.

What's next?

In 2024, PepsiCo is looking to further several key initiatives:

- Infrastructure: We plan to continue accelerating investments in collection, sortation and recycling infrastructure and explore partnerships to empower waste collectors in those markets.

- Partnership: We plan to continue building coalitions and collaborating in support of smart policies that enable the circular use of materials and build partnerships to empower our consumers to make sustainable choices through education.

- Alternative materials: We are continuing to develop the supply chain to bring compostable, renewable, bio- and paper-based materials and recyclable packaging solutions to scale.

- Design: We are exploring scalable technologies that allow us to reduce the volume of plastic in our packaging, while continuing to design for improved recyclability of our materials.

- Reuse: We plan to continue working to scale our reuse portfolio with models designed to help us reduce our use of virgin plastic per serving, decouple business growth from virgin plastic use and decrease GHG emissions.

- Advocacy: Through the UN treaty to end plastic pollution negotiations, we plan to continue advocating for supportive policy solutions and effective global rules aimed to drive towards circularity.

2Measured versus a 2020 baseline

3Our total beverage servings account for all beverage sales volume. Reuse models may include, but are not limited to, SodaStream, fountain beverages delivered in reusable containers, returnable glass and plastic bottles, and concentrates and powders sold to consumers

4Recycled plastic content allocated using the International Sustainability and Carbon Certification Plus (ISCC+) certified mass balance approach

5Fountain beverages delivered in reusable containers requiring third-party data are not currently measured

Related topics

Climate change, Deforestation, Green Bond, Sustainable product design, Sustainable sourcing, Waste